A new approach to potentiometer design, leveraging magnetic sensing technology, is gaining attention in the electronics community. According to engineering enthusiast T. K. Hareedran, traditional potentiometers, which rely on physical contacts to adjust resistance, have notable limitations, including accuracy issues, susceptibility to temperature fluctuations, and eventual wear and tear of the resistive material. The magnetic potentiometers he discusses offer a novel alternative that addresses these challenges.

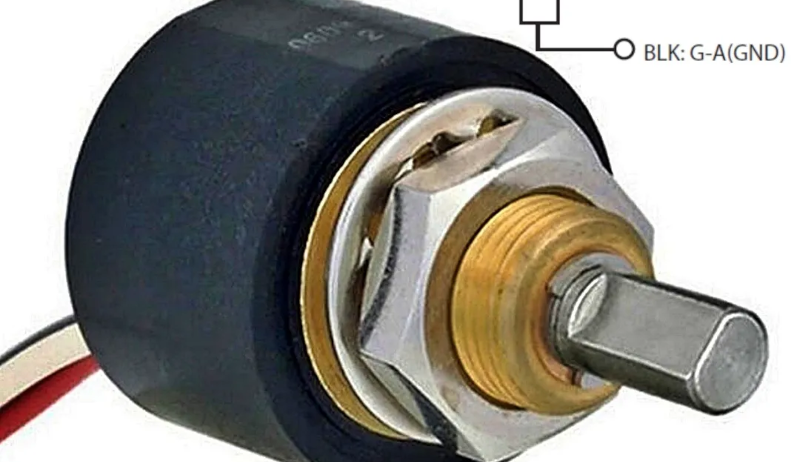

Traditional potentiometers function by moving a contact across a resistive element, but Hareedran highlights that magnetic potentiometers do not operate in the same manner. Rather than providing a resistive output, these devices can be more accurately described as rotary encoders with a voltage output. For instance, the SK22B model requires a 5 V input and produces an output voltage ranging between 10% and 90% of that input on what is referred to as the “wiper pin.”

Advantages of Magnetic Potentiometers

The use of magnetic sensing technology offers several advantages over traditional potentiometers. One significant benefit is improved linearity, as the output of a magnetic potentiometer is generally more consistent than that of its resistive counterpart. Furthermore, these devices boast a much longer lifespan, as they are less prone to the mechanical wear that affects conventional models.

While some users may prefer the simplicity of analog outputs, Hareedran notes that those seeking digital outputs could explore options with quadrature or I2C interfaces. Such interfaces would allow for more precise readings and integration into modern electronic systems. However, for applications requiring a straightforward voltage output, magnetic potentiometers present a viable solution.

In his exploration, Hareedran also details his own design process for a non-contact sensor, utilizing photosensors coupled with a gray-coded wheel featuring a single track. This innovation showcases the potential for creating custom solutions tailored to specific needs. It is worth mentioning that attention must be paid to sensor positioning to ensure optimal performance.

Future of Non-Contact Sensing

The question arises: is it possible to develop a truly non-contact resistive potentiometer? Hareedran posits that while an FET output stage could come close, it would not match the universality of traditional resistive materials, such as carbon. This ongoing exploration into alternative sensing technologies highlights the dynamic nature of the field and invites engineers and hobbyists alike to share their ideas and prototype creations.

As advancements continue, the demand for more precise, reliable, and durable sensing solutions will only grow. Magnetic potentiometers may be at the forefront of this evolution, offering innovative alternatives to traditional designs. Those interested in experimenting with these technologies are encouraged to explore the possibilities and contribute to the dialogue surrounding non-contact sensing solutions.