The Massachusetts Institute of Technology (MIT) has unveiled a new initiative aimed at enhancing manufacturing education across the United States. The program, named the Technologist Advanced Manufacturing Program (TechAMP), is designed to equip workers with essential production skills and credentials, ultimately benefiting both employees and their companies. Funded by the U.S. Department of Defense, TechAMP combines in-person lab instruction at various institutions, online lectures from MIT faculty, and interactive simulations.

Launched this fall, TechAMP is a 12-month certificate program that addresses a critical gap in the manufacturing workforce. According to John Liu, a principal research scientist at MIT, “We think there’s a gap between the traditional worker categories of engineer and technician, and this technologist training fills it.” The program aims to create new career pathways for workers, allowing them to gain a broader perspective on manufacturing operations and contribute to decision-making processes.

Collaboration and Curriculum

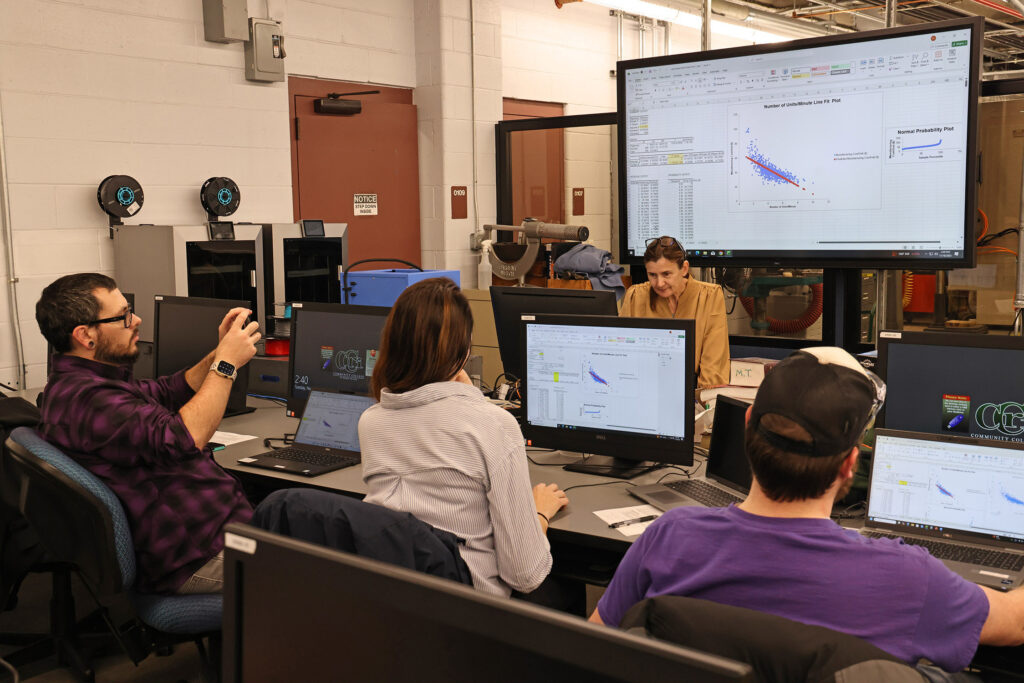

TechAMP represents a collaborative effort among several educational institutions, including the University of Massachusetts at Lowell, Cape Cod Community College, Ohio State University, and the Community College of Rhode Island. More than 70 students are enrolled in the initial cohort, reflecting a growing interest in this innovative approach to manufacturing education.

The curriculum is structured around a “hub-and-spoke” model, focusing on core manufacturing principles as the hub, while six specific training areas serve as spokes. Core topics include manufacturing process controls, workflow efficiency, leadership skills, and operations management. The six spokes—mechatronics, automation programming, robotics, machining, digital manufacturing, and design fundamentals—will adapt over time based on industry feedback.

Julie Diop, executive director of MIT’s Initiative for New Manufacturing (INM), emphasized the program’s importance: “Through TechAMP and other programs, we’re excited to reach beyond MIT’s traditional realm of manufacturing education.” This initiative is part of a broader effort to reinvigorate U.S. manufacturing, announced by MIT President Sally A. Kornbluth in May 2025.

Real-World Impact and Future Prospects

The TechAMP program includes a capstone project in which students analyze challenges within their companies. This hands-on experience can lead to significant cost savings, providing a compelling incentive for firms to invest in their employees’ training. Diop noted, “That could be a form of impact—direct value capture for the firm.”

Manufacturers are already expressing enthusiasm about the program. Michael Trotta, CEO of Crystal Engineering, highlighted the importance of high-skill roles that do not necessarily require a four-year degree. “I see TechAMP as a next logical step in developing a sustainable workforce,” he stated. Trotta and his employees collaborated with MIT to refine the curriculum, ensuring its relevance to current industry needs.

As TechAMP continues to evolve, discussions are underway with education networks in manufacturing-heavy states to expand the program’s reach. Liu expressed optimism about the response so far, indicating strong interest from organizations eager to learn more.

TechAMP stands as a testament to MIT’s commitment to enhancing the manufacturing sector by providing accessible education and fostering a skilled workforce. With its innovative approach, the program aims to redefine the role of technologists in manufacturing, creating pathways for career advancement and bridging the gap between traditional technician and engineer roles.