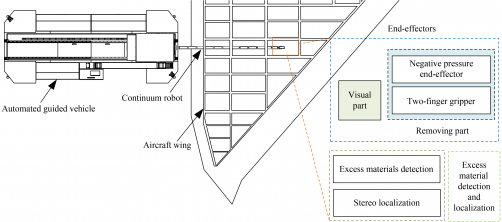

During the assembly of aircraft, excess materials such as nuts, rivets, and aluminum shavings often remain inside the wings. These leftover components pose risks to the safe operation of the aircraft, potentially leading to serious accidents. To address this issue, researchers at Beihang University have developed a novel approach for detecting and removing these excess materials using a continuum robot equipped with advanced end-effectors.

The study, titled “Detection and Removal of Excess Materials in Aircraft Wings Using Continuum Robot End-Effectors,” introduces a two-fold solution to this persistent problem. The research team, including authors Xiujie Cao, Jingjun Yu, Siqi Tang, Junhao Sui, and Xu Pei, focused on the unique challenges posed by the confined spaces within aircraft wings, which complicate manual removal efforts.

Innovative Technology for Safety

The researchers analyzed the size and weight characteristics of excess materials typically found in aircraft wings. Based on this analysis, they designed a novel negative pressure end-effector to effectively extract smaller components like nuts and small rivets. They also developed a two-finger gripper specifically for handling larger volumes of aluminum shavings. This dual approach enhances the robot’s capability to efficiently clear unwanted materials.

To improve visibility in the often poorly lit environment of aircraft wings, supplementary lighting devices were integrated into the system. This innovation ensures that the robotic components operate effectively, even in challenging conditions.

The detection and classification of excess materials are powered by the YOLO v5 algorithm, which is recognized for its efficiency in object detection. The research involved creating two training datasets tailored to the unique characteristics of the excess materials in two different types of aircraft wings.

High Accuracy and Efficient Removal

Given the limited texture features in the internal environments of aircraft wings, the researchers employed an image-matching method to enhance performance stability. This method leverages the detection results from YOLO v5 to overcome challenges associated with traditional feature point matching techniques.

Experimental results demonstrate impressive efficacy. The detection accuracy for each type of excess material exceeds 90%, with a visual localization error of less than 2 mm for four categories of excess objects. The combination of the continuum robot and its end-effectors proved to be highly effective in successfully removing these unwanted materials.

The full details of this groundbreaking research are documented in the paper “Detection and Removal of Excess Materials in Aircraft Wings Using Continuum Robot End-Effectors,” which is accessible at https://doi.org/10.1007/s11465-024-0806-2. This advancement highlights the potential for robotics to enhance safety and efficiency in the aviation industry, paving the way for safer aircraft assembly processes.