Recent advancements in the field of biomedical engineering have led to significant improvements in the design and effectiveness of 3D-printed bioactive implants. A study published in October 2023 reveals how the interaction between ink composition and printing design influences the structural integrity, strength, and bioactivity of bone implants. By carefully adjusting these variables, researchers succeeded in creating implants that not only support bone cell growth but also ensure stability, paving the way for more personalized treatment options in bone repair.

Interplay of Materials and Design

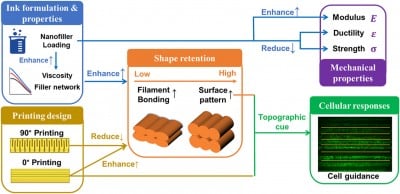

The research highlights the critical role that both material selection and design parameters play in the success of 3D-printed implants. Various materials used in the printing process can significantly affect how well the implant integrates with bone tissue. The study involved testing different ink formulations to determine the optimal composition that promotes bioactivity while enhancing the mechanical properties of the implants.

Through a series of experiments, the researchers discovered that specific combinations of materials could lead to improved cell adhesion and proliferation. This is essential for effective bone repair, as a strong bond between the implant and surrounding bone tissue is necessary for successful integration. The findings suggest that tailoring the design and materials of the implants can lead to better outcomes for patients requiring bone replacement.

Implications for Personalized Treatment

The implications of this research extend beyond technical achievements; they signify a shift towards more personalized medical solutions. With the ability to customize implants based on individual patient needs, healthcare providers can offer tailored treatments that enhance recovery and improve patient outcomes. The advancements in 3D printing technology allow for the creation of implants that match the specific anatomical and physiological requirements of each patient, making surgeries more effective.

As the demand for personalized medical solutions increases, the integration of advanced materials and innovative design in 3D printing becomes increasingly important. This research not only contributes to the scientific community but also has the potential to transform how bone repair surgeries are conducted worldwide.

In summary, the recent study on 3D-printed bioactive implants underscores the importance of material and design interplay in developing effective medical solutions. The ability to engineer implants that foster bone cell growth while maintaining structural stability represents a substantial leap forward in personalized treatment for bone repair. This research marks a promising step toward improving the quality and effectiveness of surgical interventions in the field of orthopedics.