A team of researchers from the University of St Andrews has made a significant breakthrough in recycling household plastic waste, converting it into a valuable building block for anti-cancer medications. This innovative process, published in the journal Angewandte Chemie International Edition, specifically targets polyethylene terephthalate (PET) waste, commonly found in plastic bottles and textiles.

Revolutionizing Plastic Recycling

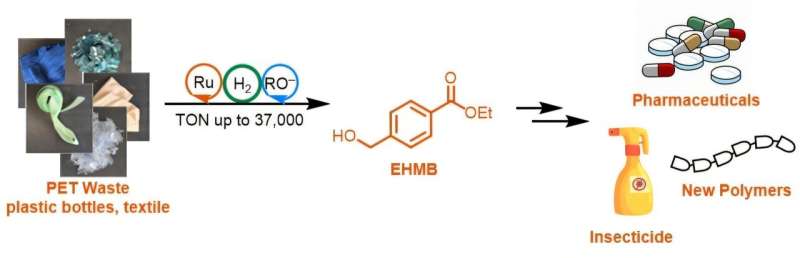

The research focuses on the chemical recycling of PET, a process that disassembles long polymer chains into smaller units known as monomers or other useful chemicals. The team employed a ruthenium-catalyzed semi-hydrogenation technique to effectively depolymerize PET into ethyl-4-hydroxymethyl benzoate (EHMB). This compound is essential for synthesizing several critical pharmaceuticals, such as Imatinib, a widely used anti-cancer drug, and Tranexamic acid, which aids in blood clotting.

Current production methods for these medications typically rely on fossil-derived materials and involve hazardous reagents that generate significant waste. The new approach promises not only to reduce environmental impact but also to provide a sustainable alternative for pharmaceutical manufacturing.

Environmental Benefits and Economic Feasibility

The study highlights the environmental advantages of this new recycling method. Using a comparative hot-spot analysis within a streamlined life cycle assessment, researchers pinpointed the stages of production that pose the greatest ecological risks. This targeted assessment allows for more effective improvements in the recycling process.

Dr. Amit Kumar, the lead author from the School of Chemistry at St Andrews, expressed enthusiasm about the discovery, stating, “We are excited by this discovery, which reimagines PET waste as a promising new feedstock for generating high-value APIs (Active Pharmaceutical Ingredients) and agrochemicals.” He emphasized that this innovative method could significantly expedite the transition to a circular economy by enabling the upcycling of plastic waste into high-value products rather than merely reproducing the same class of plastics.

Collaboration with TU Delft in the Netherlands has further enriched this research. Professor Evgeny Pidko, who leads the collaborative efforts, noted the importance of catalyst efficiency. “For catalytic upcycling to become practical, the catalyst must operate efficiently at low loadings and maintain activity over long periods,” he explained. His team utilized detailed kinetic and mechanistic analysis to optimize catalyst performance, achieving record turnover numbers of up to 37,000.

The manufacturing of pharmaceuticals typically generates substantial waste per kilogram of product, underscoring the need for more sustainable processes. Experts from Merck KGaA, including Dr. Benjamin Kuehne and Dr. Alexander Dauth, highlighted the urgency of developing innovative chemical processes and raw materials with a reduced environmental footprint.

The research demonstrates a promising path toward utilizing waste materials in the pharmaceutical industry, with potential applications extending beyond cancer treatment. By transforming PET waste into valuable intermediates, this groundbreaking work paves the way for a more sustainable future in both healthcare and environmental conservation.

For more information, the full study is available in Angewandte Chemie International Edition under the title “From Plastic Waste to Pharmaceutical Precursors: PET Upcycling through Ruthenium Catalysed Semi-Hydrogenation.”