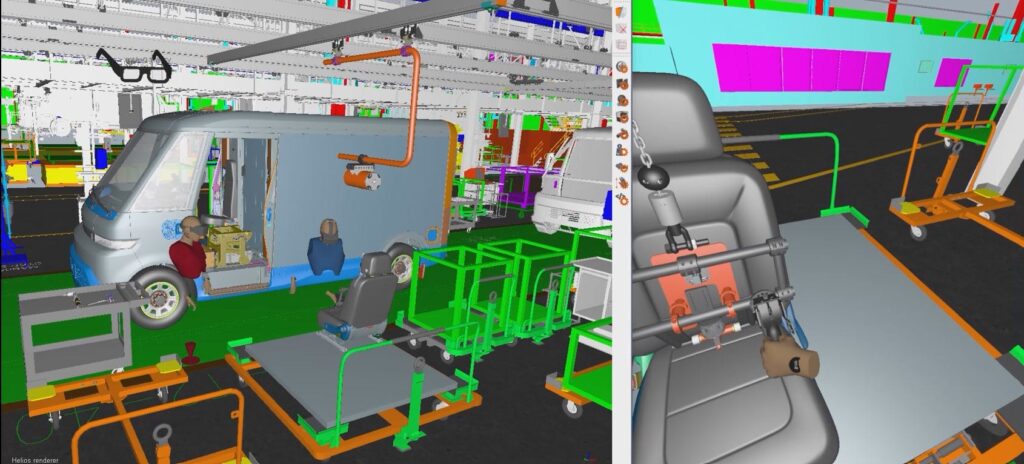

General Motors (GM) has unveiled a significant advancement in its manufacturing processes with the launch of a new virtual reality (VR) assembly center at its Global Artisan Innovation Center in Warren, Michigan. This facility, one of the largest VR labs worldwide, has already identified and resolved 494 issues in vehicle design and assembly without requiring physical prototypes. The integration of virtual reality and artificial intelligence (AI) is transforming how GM approaches pre-production, enabling employees to tackle complex manufacturing challenges more efficiently.

The VR assembly center allows manufacturing teams from various GM operations to collaborate on vehicle design and assembly in a virtual environment. This year, GM hosted six major build events that brought together employees from different locations, including those who would traditionally need to travel for in-person meetings. Max Sikorski, who leads the virtual reality team, emphasized the effectiveness of this approach: “They see each other, talk to each other — a real application of a metaverse.” By using VR technology, GM has reduced travel costs and improved communication among teams, making the problem-solving process more effective than traditional methods.

Since the program’s initiation in 2022, every future vehicle at GM will undergo testing in this virtual environment. The aim is to fine-tune product development and manufacturing processes well in advance, allowing for the identification of potential issues early on. Sikorski noted, “If we catch an issue now, it’s not going to be an issue later,” highlighting the proactive nature of the program.

Innovative Approaches to Ergonomics and Safety

One of the most compelling aspects of GM’s VR program is its focus on ergonomics and worker safety. Dwaine Carswell, a virtual assembly inspector with over 15 years of assembly experience, plays a crucial role in this process. By using motion sensors, Carswell’s movements are tracked and translated into a virtual duplicate. This technology helps identify potential strain or injury risks in real time, ensuring that the assembly tasks are safe for all workers. The data is derived from the U.S. Car Ergonomic Model, which assesses the physical requirements for both male and female workers.

Sikorski’s team has already resolved more than 50 ergonomic-related safety issues since the program’s inception. The goal is to create a work environment where all employees, regardless of their physical attributes, can perform their jobs safely. “It’s beneficial for GM, because we want people to be able to swap in and out of jobs,” Sikorski explained. “But it’s also beneficial for the people because if you are a smaller person or a bigger person, you’re not going to be asked to do a job that wasn’t validated for your size.”

As GM continues to refine its VR technology, the company is considering upgrades to the motion capture suits used in the process. Currently, the Xsens suits provide a digital representation of the workers, but advancements similar to those used in the film industry could enhance the realism and efficiency of the program.

Streamlining Production and Reducing Costs

The shift towards virtual assembly has led to a significant reduction in the resources required for prototype development. Traditionally, creating a prototype vehicle could cost up to $100,000 and consume vast amounts of materials and labor. With the VR program, GM has simplified this process, allowing for rapid adjustments without the need for physical prototypes.

Karsten Garbe, the plant director for global pre-production operations at GM, noted that the transition from physical fabrication to virtual assembly has resulted in a more streamlined operation. “This used to be filled with workers building prototypes. Now, as you can see, it is almost empty,” he said during a visit to the facility on September 8, 2023. The company has successfully transitioned several employees from prototype construction to other roles within the organization, leveraging their skills in a variety of departments.

This innovative approach not only saves time and money but also enhances the quality of the manufacturing process. By utilizing historical data and AI, GM can quickly identify and address potential issues that may arise during production. “It’s impossible for any one engineer to know what happened 45 years ago. It’s easy for an AI to know that,” Sikorski explained, emphasizing the efficiency gained through this technology.

As GM continues to evolve its manufacturing practices, the integration of virtual reality and AI is proving to be a game-changer for the automotive industry. The company’s commitment to innovation positions it as a leader in the field, paving the way for a more efficient and safer future in vehicle production. With each advancement, GM is not only enhancing its operational capabilities but also ensuring a better working environment for its employees.