A new study has unveiled a groundbreaking micro-grinding process aimed at improving orthopedic surgeries by enhancing the machinability of biological bone. Researchers from several institutions, including Qingdao University of Technology and the University of Southern California, have developed a technique known as ultrasonic vibration-assisted nanoparticle jet mist cooling (U-NJMC). This innovative approach addresses significant challenges in current micro-grinding practices, which often lead to thermal damage and complications during recovery.

The motivation behind this research stems from the limitations of existing micro-grinding methods. Traditional techniques struggle with inadequate cooling, poor visibility during procedures, and excessive grinding forces that can harm bone and surrounding tissues. The U-NJMC process combines the benefits of ultrasonic vibration with nanoparticle jet mist cooling to enhance grinding efficiency and reduce thermal impact.

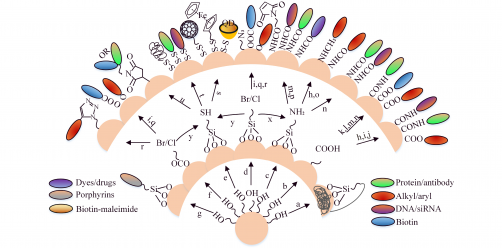

In the study titled “Machinability of ultrasonic vibration-assisted micro-grinding in biological bone using nanolubricant,” the team, led by Yuying YANG, Min YANG, and Changhe LI, examined fresh bovine tibial dense bone, which closely resembles human bone in mechanical properties. Using a diamond micro-grinding tool, they conducted experiments under six distinct conditions: dry grinding, drip irrigation, ultrasonic vibration, minimum quantity lubrication, nanoparticle jet mist cooling, and U-NJMC.

The analysis focused on several key performance indicators, including grinding force, friction coefficient, specific grinding energy, and grinding temperature. Results indicated that the grinding force varied depending on the direction of the bone tissue. Notably, the section grinding force was found to be the highest, followed by the side and surface grinding forces.

Among the six grinding conditions tested, U-NJMC demonstrated superior performance. Its minimum normal grinding force was recorded at 1.39 N, while the tangential grinding force was 0.32 N. These figures represent reductions of 75.1% and 82.9% compared to dry grinding, respectively. Furthermore, U-NJMC achieved the lowest friction coefficient and specific grinding energy across all conditions, with reductions of 31.3% to 83.0% in specific energy compared to the other methods.

The grinding temperature during U-NJMC operations was also significantly lower, averaging around 26.2 °C. This temperature is 33.5% and 10.0% lower than those recorded for ultrasonic vibration and nanoparticle jet mist cooling alone, respectively. These findings suggest that U-NJMC effectively mitigates the issues of high grinding force and temperature, making it a promising technique for clinical applications in orthopedic surgery.

The comprehensive results of this research highlight the potential of U-NJMC as a reliable solution for the challenges faced in biological bone micro-grinding. The team’s work not only contributes to advancements in orthopedic procedures but also lays the groundwork for further exploration in the integration of mechanical science and biomedicine.

For more detailed insights, the full text of the study is available at: https://doi.org/10.1007/s11465-022-0717-z.